Levitech

Levo Levitor

Levitrack

Levo SiC RTA

Engineering

Levitech is a global player in semiconductor industry for Rapid Thermal Processing (RTP) solutions and in photovoltaic industry for ALD applications. Levitech offers engineering support for customer projects.

The Levitor LEVO is a single-wafer Rapid Thermal Processing- system

The Levitrack Atomic Layer Deposition (ALD) system is designed for high-volume production

The Levitor LEVO SiC RTA is a single-wafer Rapid Thermal Annealing system specifically designed for Silicon Carbide (SiC) wafers.

We deliver precision-engineered solutions using the latest in automation and assembly technology. From concept to production, our team ensures unmatched quality and innovation at every step.

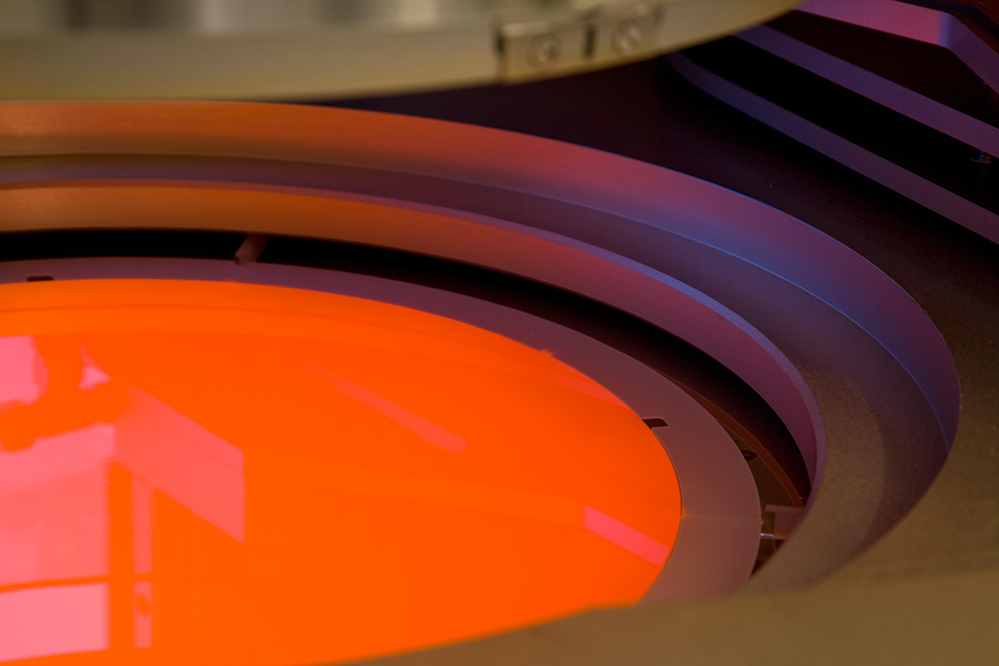

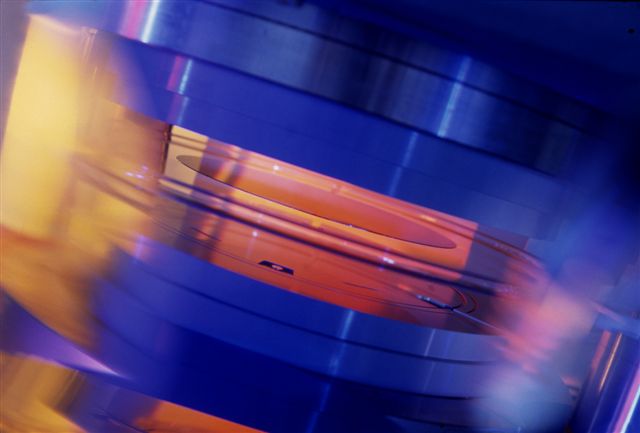

The defining feature of the Levitor technology is its ability to utilize high temperature gas to suspend the wafer during processing. As the wafer does not come into contact with the walls of the chamber, we say that the gas ‘levitates’ the wafer. Thus the names Levitech, Levitor and Levitrack are derived from the verb to levitate, defined as: to cause to rise in the air and float as if in defiance of gravity.

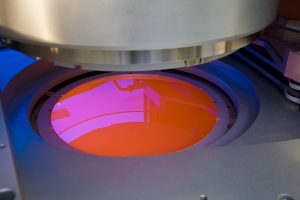

Levitor LEVO

The Levitor LEVO is a single-wafer Rapid Thermal Processing- system is based on the unique concept of conduction rather than the conventional method of radiation heating. This technology is used to rapidly heat and cool-down wafers.

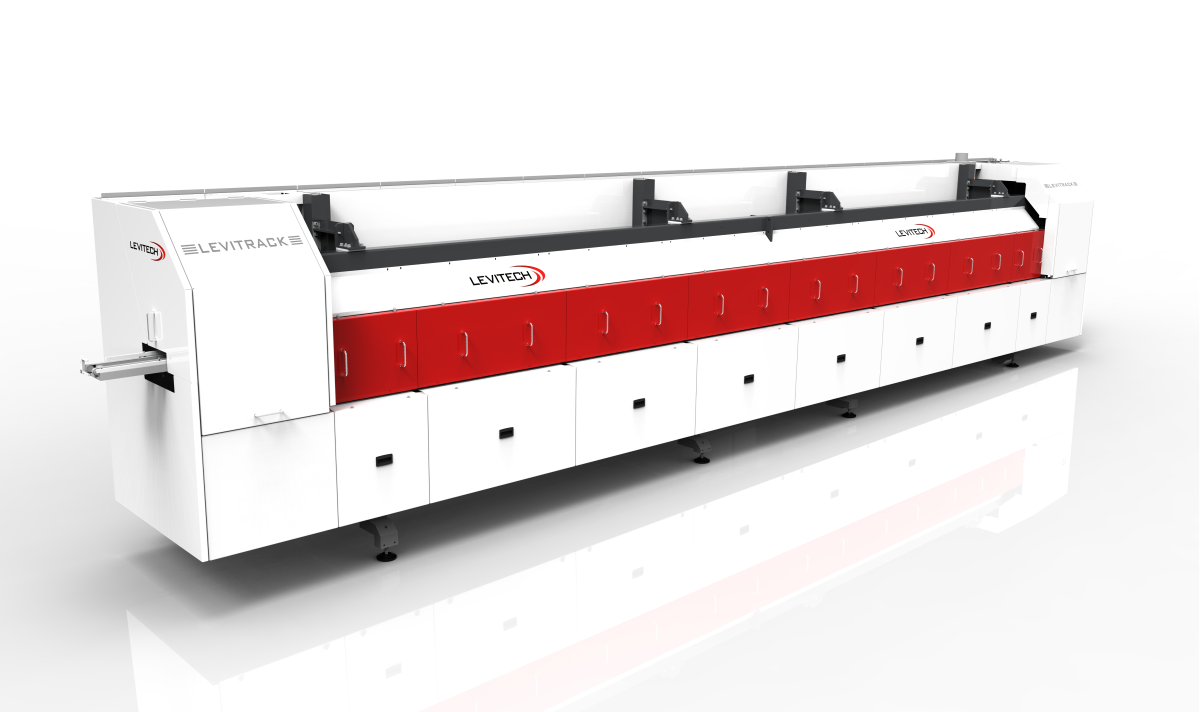

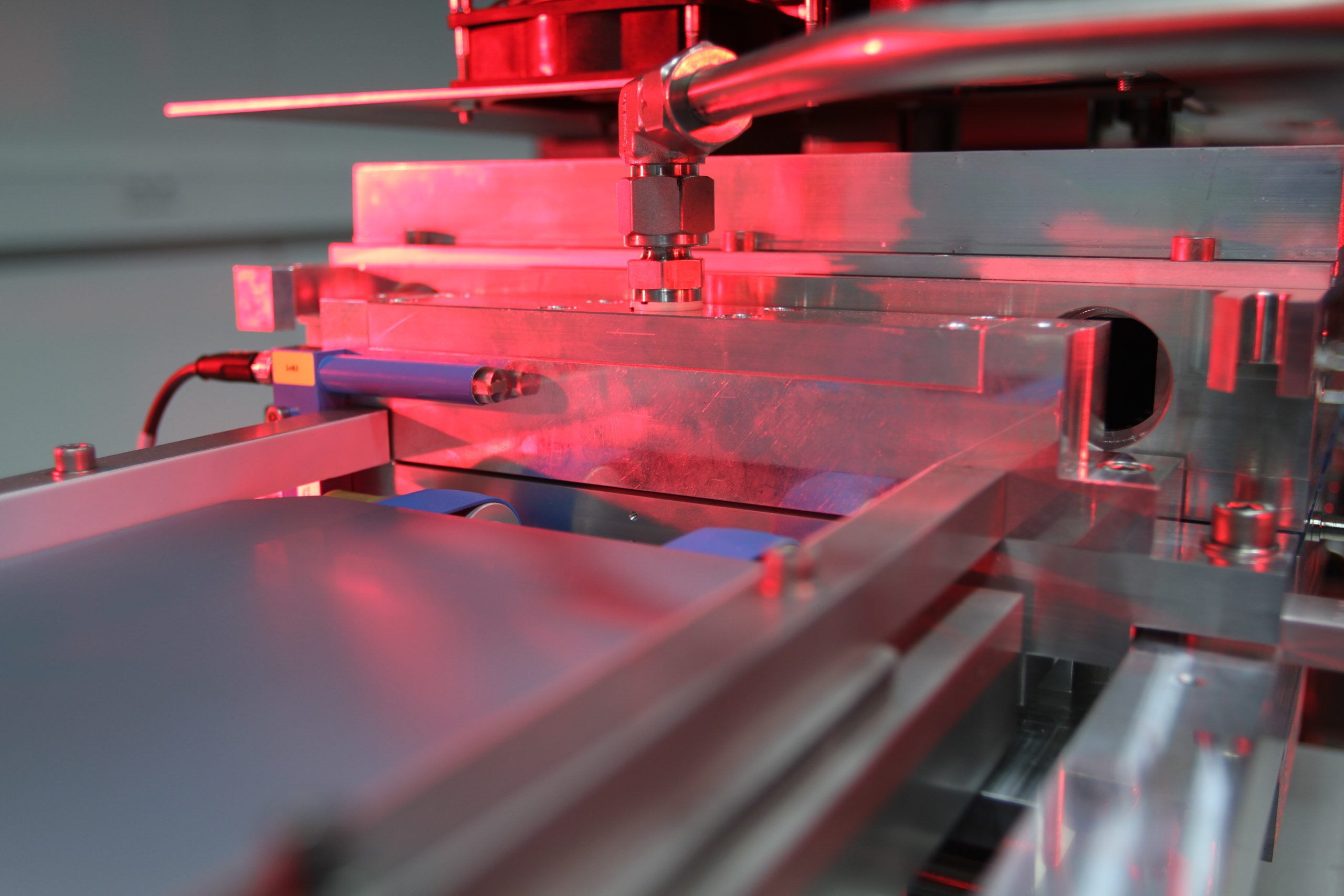

Levitrack

The Levitrack Atomic Layer Deposition (ALD) system is designed for high-volume production, depositing ultra-thin layers to improve solar cell efficiency.

It generates passivation and intermediate multi-stack layers, which are applied in the tandem cell of a standard cell with a perovskite cell on top.

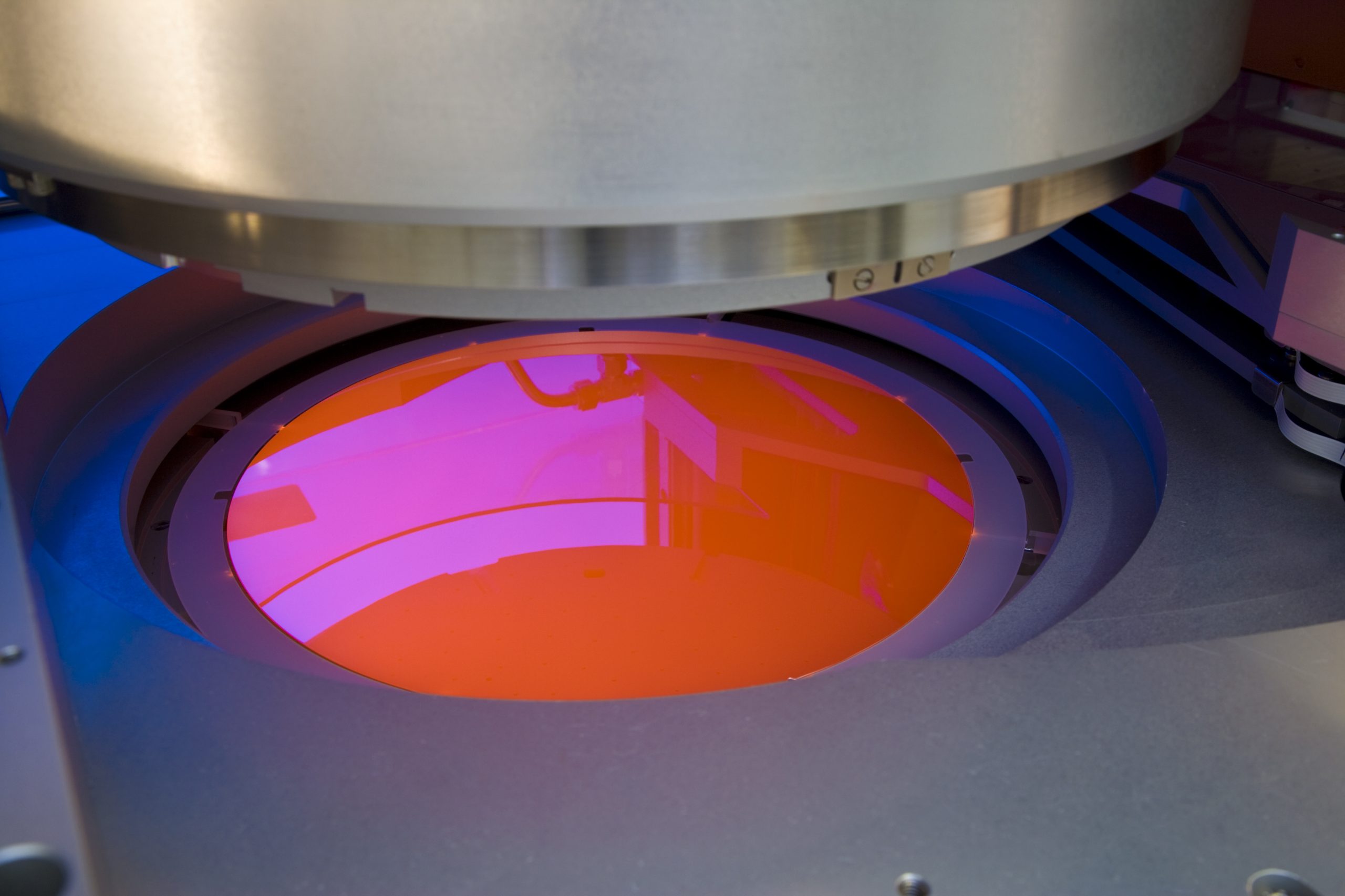

LEVO SiC RTA

The Levitor LEVO SiC RTA is a single-wafer Rapid Thermal Annealing system specifically designed for Silicon Carbide (SiC) wafers.

It utilizes conduction-based heating instead of traditional radiation heating, ensuring fast and efficient wafer heating and cooling. This enables precise temperature control from 100°C to 1200°C, delivering excellent uniformity, high throughput, and repeatability—crucial for SiC processing.